The Precision Craft of Diecasting: Revolutionizing Manufacturing

The Precision Craft of Diecasting: Revolutionizing Manufacturing

Blog Article

Diecasting is a diverse and widely used manufacturing process which involves the injection of molten metal into a mold chamber under the pressure of a high. It is extremely efficient for producing large volumes of complicated metal parts, with excellent dimensional accuracy as well as smooth finish on the surface. Diecasting's process, the materials and techniques of diecasting are crucial to many industries, and it is an integral part of modern manufacturing. This article explores the fundamentals of diecasting, its advantages, and its diverse applications throughout the field.

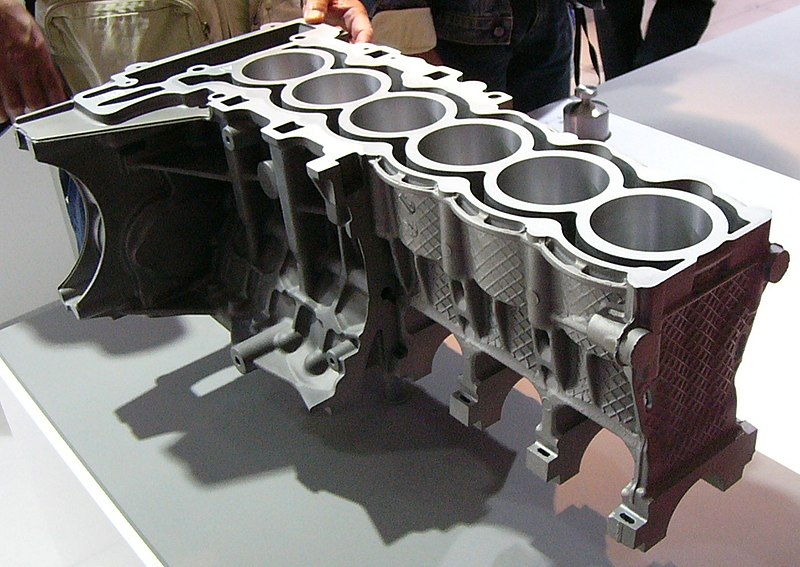

Diecasting starts with the creation of top-quality steel molds, known as dies. They are made to withstand the intense pressures and high temperatures that molten metal experiences. These dies are meticulously crafted to record intricate details and keep tight tolerances ensuring that each cast part is in compliance with the specific requirements of design. The casting process involves metals like aluminum, magnesium, zinc, and copper are heated and introduced into the die cavity under high pressures. Rapid injections and cooling result in parts that exhibit excellent dimension stability as well as a smooth surface. The precision of the dies permits the production of components with complex geometries that are usually impossible with other methods of production.

One of the main benefits of diecasting lies in its capacity to make parts with exceptional dimensional accuracy and smooth surface finishes. This is because high-pressure injection makes sure that every part of the mold is reproduced which results in components which meet the strictest tolerances and require little to no post-production work. This level of precision is particularly beneficial for creating complex geometries and fine details that might be difficult to attain using other methods of manufacturing. Additionally, the repeatability of diecasting makes it ideal for large-scale production, ensuring the sameness across thousands of components. The effectiveness of this process also leads to significant cost savings since it decreases waste material and costs for labor.

Diecasting is also an excellent method for creating components with excellent mechanical properties. Rapid cooling of molten metal during the casting process creates the formation of fine grains, increasing the durability and strength of the final product. Dies makes diecast parts appropriate for uses that require high performance and reliability. In the automotive sector Diecast components are utilized for transmissions, engines, and structural components. their strength-to-weight ratio is critical for safety and vehicle efficiency. In the aerospace sector diecast parts contribute to the development of lighter but solid structures, which are crucial to optimizing fuel efficiency and performance. To generate additional details kindly check out Senadiecasting

The materials used in diecasting are crucial in determining the characteristics and efficiency of the final product. Aluminum is one of the most commonly used materials due to its excellent strength-to-weight ratio, corrosion resistance, along with its high electrical and thermal conductivity. Zinc alloys are also very popular, offering high durability, strength, and the capability of creating products with exquisite particulars. Magnesium alloys benefit from the advantages of being the lightest steel, which makes them perfect for use in areas where weight reduction is critical. Copper alloys, though more rare, are employed due to their high electrical conductivity and resistance to corrosion. The selection of the material is based on the particular requirements of the job, such as mechanical properties, physical conditions in the environment, and also cost issues.

Diecasting is an essential manufacturing process that combines precision, efficiency, and versatility. Its capacity to manufacture complex, high-quality components with outstanding mechanical properties make it a necessity in many industries. Diecasting's efficiency as a mass-production process, with its cost and material benefits, underscores its value in modern manufacturing. Since the need for high-quality and dependable components continues increase, diecasting will continue to be a cornerstone technology, driving innovations and supporting the manufacturing of high-end products that can meet requirements of the market. By its continual advancement and use, diecasting exemplifies the combination of engineering expertise and manufacturing knowledge, establishing its importance in the next phase of industrial production.